|

|

|

現在位置:首頁

>> 產品與服務

>> NIIGATA重油發電機 |

|

|

|

NIIGATA重油發電機 |

|

|

|

28HLX Series

Niigata is proud to introduce the

new 28HLX medium speed high

performance diesel engine series.

With a bore & stroke of 280×400mm,

at 720 or 750 rpm, this model packs

a maximum continuous rating of 375

kWm per cylinder at standard

reference conditions. Fuel

consumption rate is improved to very

competitive low levels and this

model is designed to efficiently

burn low grade bunker fuel of up to

700 cSt at 50degC

|

|

Each engine component is a

successful product of Niigata's

vigorously continuing

R & D program in design and

manufacturing processes, towards

higher reliability and efficiency.

Important features of this engine

are the rigid monobloc hanger type

crankcase, highly balanced large

journals robust crankshaft with high

capacity bearings, horizontal split

connecting rod large-end caps,

integral machine cams with the

segmented cam shaft per cylinder,

more effective cooling,

turbocharging and lubrication, high

pressure direct fuel injection

system, among other improvements.

|

|

|

|

The engine design also painstakingly

took into consideration the

important aspects of easy and simple

maintenance featuring wider

crankcase doors, 4-stud cylinder

heads, swing arm type cam followers,

trunk type manifolds and channels

for the charge air and jacket

cooling water, all built-in in the

crankcase. |

With a total of over 20 million kWm

of hard working diesel engines

delivered worldwide over the past 8

decades, Niigata, with this vast

experience has made the 28HLX

another technological breakthrough

in the field of medium speed, medium

bore diesels. This compact high

performance high output and

environment friendly engine model is

undoubtedly a step ahead in the

global search for the ideal engine

to satisfy the specific size range

in power or industrial requirements

aimed towards healthier returns on

investments.

|

|

Manufactured in our ISO

9001-certified OHTA and NIIGATA

engine plants the 28HLX comes in

convenient sizes from 6 in-line to

18 Vee cylinder configurations with

typical ratings of 2 160 to 6 750

kWm. |

|

|

|

FEATURES |

|

Optimized Combustion Efficiency

Features |

| |

* NCCS

(Niigata Compact Constant Pressure

Turbocharging System).

* 25% output capacity rise compared

to the conventional engine.

* Higher maximum combustion pressure

(Pmax) of up to 20 MPa.

* Brake mean effective pessure

raised to 2.44 MPa, mean piston

speed raised to 10.0 m/s, 18%

and 8% higher respectively than

the conventional diesel engine.

* Specific output rate of 24.4

MPa.m/s noted as the highest level

in the world for this engine

size (The highest for

conventional Niigata diesel engines

has been 22.5 MPa.m/s).

* High pressure, 147.1 MPa, short

duration fuel injection system.

* Cylinder liners equipped with

Fire Rings.

* Capable of burning low grade

bunker fuel of up to 700 cSt at

50degC |

| |

Major

Components Designed and Furnished

for Superior Reliability,

Low Vibration |

| |

* Designed by FEM

(Finite Element Method) stress

calculation.

* Stress measurement confirmation by

component element tests.

* NCI (Nodular cast iron)

highly rigid monobloc double-walled

hanger type crankcase.

* Special chrome-molybdenum steel

forged crankshaft with large main

and crankpin journals and

carefully counterweighted for

high degree of balance. Very low

vibration levels. |

| |

|

Simplified Maintenance and

Inspection Features |

| |

* Four-stud

cylinder head fastening.

* Wide air trunk and cooling water

built-in with crankcase.

* Special hydraulic tools for

disassembly and assembly work.

* Swing arm type cam followers.

* Unitized per cylinder segmented

cam shaft.

* Total weight and component parts

reduced by 12% and 25%,

respecitively, compared to similar

conventional models. |

|

MODEL |

6L28HLX |

8L28HLX |

12V28HLX |

16V28HLX |

18V28HLX |

|

Type |

Turbo

charged, 4 cycle diesel engine with

air cooler |

|

Configuration |

In-line-form |

Vee-form |

|

Cylinders |

6 |

8 |

12 |

16 |

18 |

|

Bore |

280

mm |

|

Stroke |

400

mm |

|

Displancement |

24.63

L/cyl. |

|

Rotation

direction |

Clockwise (Viewing from the coupling

side) |

|

Starting system |

By

compressed air |

|

Fuel injection

system |

Direct injection |

|

Cooling method |

Water

cooled |

|

Turning method |

Gear

type, motor drive |

|

Fuel oil |

Diesel oil or heavy fuel oil |

|

MODEL |

6L28HLX |

8L28HLX |

12V28HLX |

16V28HLX |

18V28HLX |

|

Frequency |

50/60

Hz |

|

Max . combustion

pressure |

20

MPa (204 kgf/cm2) |

|

Mean effective

pressure |

2.44

MPa (24.85 kgf/cm2) |

|

Engine output for 50 Hz

|

2 250 kWm |

3 000 kWm |

4 500 kWm |

6 000 kWm |

6 750 kWm |

|

(375

kWm/cyl.) |

|

Generator output |

2 150 kWe |

2 880 kWe |

4 330 kWe |

5 790 kWe |

6 510 kWe |

|

Engine speed |

750

min-1 (750 rpm) |

|

Mean piston

speed |

10.0

m/s |

|

Engine output for 60 Hz

|

2 160 kWm |

2 880 kWm |

4 320 kWm |

5 760 kWm |

6 480 kWm |

|

(360

kWm/cyl.) |

|

Generator output |

2 060 kWe |

2 760 kWe |

4 160 kWe |

5 550 kWe |

6 250 kWe |

|

Engine speed |

720

min-1 (720 rpm) |

|

Mean piston

speed |

9.6

m/s |

|

>>

|

The output figures shown in the

tables represent the rating under

the following standard reference

conditions. If site conditions are

different from the standard

reference conditions, the output

shall be adjusted from the above

figures.

Standard Reference Conditions : |

| |

|

1) Ambient

temperature: 40degC

2) Cooling water (air cooler inlet)

temperature: 35degC

3) Atmospheric pressure: 101.3 kPa

(760 mm Hg)

4) Generator output is subject to

generator efficiency |

|

MODEL |

Principal Dimensions (mm) |

Mass (t) |

|

A |

B |

C |

D |

E |

Engine |

Generator |

|

6L28HLX |

4 825 |

2 780 |

7 605 |

2 855 |

2 335 |

23 |

10 |

|

8L28HLX |

5 920 |

3 250 |

9 170 |

2 855 |

2 406 |

31 |

13 |

|

12V28HLX |

6 315 |

3 450 |

9 765 |

3 487 |

2 527 |

38 |

17 |

|

16V28HLX |

7 035 |

3 550 |

10 585 |

3 335 |

2 553 |

50 |

20 |

|

18V28HLX |

8 415 |

3 550 |

11 965 |

3 785 |

2 780 |

57 |

22 |

Note: The mass and dimensions of generators

shall be subject to electrical design.

|

|

|

DESIGN & CONSTRUCTION FEATURES |

|

Pistons

Connecting Rods

Cylinder Liners

Cam Shafts

Cylinder Heads

|

|

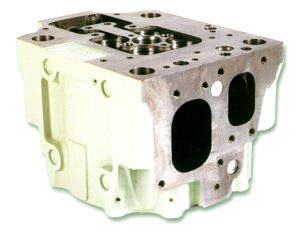

1 Crank Case |

| |

Made of

NCI (Nodular Cast Iron),

the mono- block type

double-walled hanger type

box structure

crankcase/cylinder block is

carefully designed for

sufficient strength and

rigidity with low vibration

characteristics necessary

for the high Pmax of this

engine. The wide area low

friction loss charge air

chamber, jacket water

cooling channels, and

camcases are cast-integrated

into the block. |

|

2 Crankshaft &Main

Bearings |

| |

The

crankshaft is forged from a

special chrome-molybdenum

steel stock. The large main

and crankpin journals keep

the bearing load and

torsional stresses low even

with the high Pmax of this

engine. Carefully designed

balance weights ensure a

very high degree of balance

factor for sufficient and

consistent bearing oil film

thicknees. Thin-backed

3-layer kelmet type bearings

of high surface pressure

resistance are provided for

the main and crankpin

journals for long bearing

service life. |

|

3 Pistons |

| |

Lightweight

pistons of improved design

for high Pmax capacity is

sucessfully adopted for this

engine. Three compression

rings and one oil control

ring per piston, are

provided. The wide cooling

spaces in the crowns ensure

a very effective cooling by

forced feed lubricating oil

shaking system. The

thin-walled skirt reduces

total piston weight and

inertia and easily

harmonizes with the

expansion coefficient of the

cylinder liner. |

|

4 Connecting Rods |

| |

Made of

special forged steel the

connecting rod is of the

two-piece design consisting

of a horizontal-split large

end bearing housing to suit

the large diameter crankpin

for improved reliability and

lower bearing load stress. |

|

5 Cylinder Liners |

| |

The liners

are centrifugal cast and

nitrided internally. Very

low wear rate is assured.

Replaceable fire rings

are fitted at the top

portion combustion zone.

This reduces polishing of

walls by the solid carbon

particles from combustion,

thus keeping the desired

wall roughness for oil film

dwell optimizing the

function of the piston rings

for longer periods with

reduced lubricating oil

consumption The upper

engaging section of the

liners has a rigid thick

wall structure with bored

water cooling system

for uniform thermal stress

needed for high Pmax

operation. The lower portion

of the liners are air-cooled

with the charge air

effectively reducing cold

corrosion wear. |

|

6 Cam Shafts |

| |

The cam

shaft consists of segments,

unitized per cylinder

with the fuel, air intake

and exhaust cams machined

integrally from a single

special forged steel stock.

Each segment is bolted

axially to that of the next

cylinder's through a common

journal segment. By this

system maintenance work is

greatly simplified. |

|

7 Cylinder Heads |

| |

The cylinder

heads are made of CV

(compacted vermicular) cast

iron which optimizes the

distribution of mechanical

stress and provides better

thermal conductivity much

needed for high Pmax

operation. Thermal stress is

reduced by bore-cooling.

A four-stud design is

applied to provide for

larger intake and exhaust

ports, reducing air and gas

flow losses. Maintenance

work, consequently, is also

simplified. |

|

8 Exhaust Valves |

| |

Nimonic

(special high corrosion

resistant alloy) exhaust

valves with mechanical

"rotomat" rotators are

applied for long reliable

operation. |

|

9 Fuel InjectionPumps &

Fuel Injectors |

| |

To realize

higher combustion efficiency

and better fuel economy

high pressure fuel

injection pumps (147.1 MPa),

mini-mass injector,

and short cycle injection

pipe thorough the cylinder

head are applied. The

injector nozzle spray holes

are specially treated to

increase discharge

coefficient thus improving

combustion and prolonging

nozzle tip service life. |

|

| |

|

| |

|

| |

|

|

|

|

|

|

|

|