|

|

| 現在位置:首頁

>> 產品與服務

>> NIIGATA重油發電機 |

|

|

|

NIIGATA重油發電機 |

|

|

|

32CLX

|

HIGH

RELIABILITY |

|

HIGH

EFFICIENCY |

The name 'Niigata Diesel' has gained

a wide reputation from the domestic

and foreign users involved, as a

'reliable and high performance

diesel engine'

Now, by consolidating its wide

diesel engine experience with

state-of-the-art technologies,

NIIGATA proudly presents its newly

developed, high performance Model

32CLX diesel, specially designed to

burn heavy fuel up to 700cSt (at 50

degC) viscosity and provide low fuel

consumption. |

|

|

|

TO BURN

HEAVY FUEL |

|

EASY

MAINTENANCE |

|

|

|

|

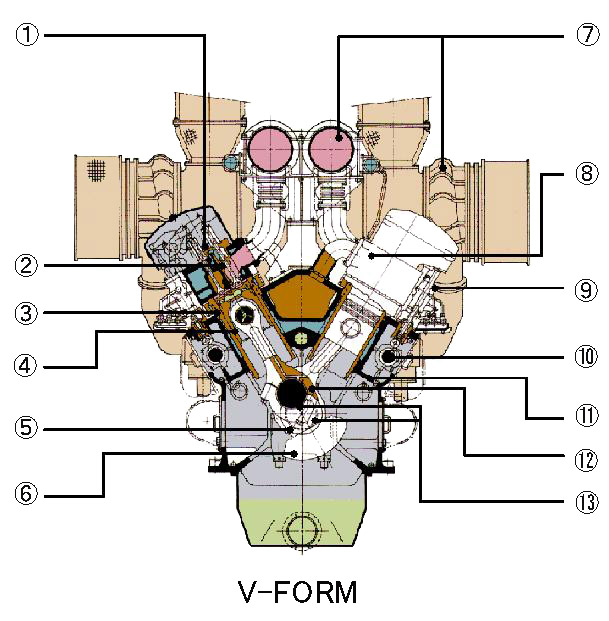

NIIGATA 32CLX ENGINE, CROSS SECTION |

|

INJECTOR NOZZLE TEMPERATURE

CONTROLLED BY CYLINDER COOLANT FOR

USE OF HEAVY FUEL. |

|

| |

|

TO BURN HEAVY FUEL |

|

|

HIGH-EFFICIENCY TURBOCHARGERS AND

CONSTANT-PRESSURE OR IMPULSE

SUPERCHARGING. |

|

| |

|

HIGH PERFORMANCE. |

|

|

|

'CAGE' TYPE VALVES (VALVE SEATS

COOLED FOR USE OF HEAVY FUEL) AND

VALVE ROTATORS. |

|

| |

LONG LIFE AND

EASY MAINTENANCE

USING HEAVY FUEL. |

|

|

RIGID CYLINDER HEAD WITH UNIQUE

INLET AND EXHAUST PORT ARRANGEMENT. |

|

| |

HIGH RELIABILTY.

|

|

|

SPECIAL WEAR-RESISTANT, CAST IRON,

BORE-COOLED CYLINDER LINERS. |

|

| |

|

REDUCED WEAR. |

|

HIGH PRESSURE FUEL INJECTION PUMPS.

|

|

| |

|

LOW FUEL CONSUMPTION. |

|

|

TWO PIECE PISTONS WITH HEATRESISTANT

STEEL CROWNS AND DUCTILE CAST IRON

SKIRTS. |

|

| |

|

HIGH, RELIABLE PERFORMANCE. |

|

LATERALLY REMOVABLE CAMSHAFT.

|

|

| |

EASY MAINTENANCE.

|

|

|

SPECIAL 'R-R' PROCESS FORGED STEEL

CRANKSHAFT WITH TORSIONAL VIBRATION

DAMPER AT COUNTER-COUPLING END. |

|

| |

|

HIGH RELIABILITY. |

|

RIGID CYLINDER BLOCK.

|

|

| |

|

HIGH RELIABILITY. |

|

BALANCED WEB CONTERWEIGHTS.

|

|

| |

|

REDUCED VIBRATION |

|

|

STAMP FORGED, SPECIAL STEEL

CONNECTING RODS. GROUND SHANK AND

SERRATED MATCHING BIG ENDS. |

|

| |

|

HIGH RELIABILITY. |

|

| |

|

SHELL-TYPE, 'KELMET' (COPPER LEAD

ALLOY) BEARINGS. |

|

| |

|

LONG SERVICE LIFE. EASY MAINTENANCE. |

|

|

MODEL |

L32CLX |

V32CLX |

|

Type |

4-cycle with turbocharger(s) and air

cooler(s) |

|

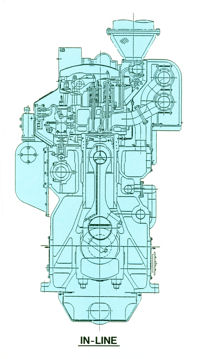

Configuration |

In-line |

60 degC

V-form |

|

Cylinders |

6 or 8 |

12, 16 or 18 |

|

Bore |

320 mm |

|

Stroke |

420 mm |

|

Displacement |

33.76 l/cyl. |

|

Rotation direction |

Clockwise (Viewing from the coupling side) |

|

Fuel oil |

Gas oil, diesel oil or heavy fuel |

MODEL

ITEM |

6L32CLX |

8L32CLX |

12V32CLX |

16V32CLX |

18V32CLX |

|

Frequency |

Hz |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

60 |

50 |

50 |

|

Engine Output |

PS |

3

000 |

4

000 |

6

000 |

8

000 |

9

000 |

|

kW |

2

206 |

2

942 |

4

413 |

5

884 |

6

619 |

|

Generator Output |

kW |

2

100 |

2

800 |

4

240 |

5

680 |

6

400 |

|

Engine Speed |

rpm |

600 |

Brake Mean Effective

Pressure |

MPa

(kgf/cm2) |

2.18

(22.2) |

|

Mean Piston Speed |

m/s |

8.4 |

>>

|

The

output figures shown in the table represent

the rating under the following standard

reference conditions. If site conditions is

different from the standard reference

conditions, the output shall be adjusted

from the above figures.

Standard Reference Conditions : |

| |

|

1) Ambient temperature: 40

degC

2) Cooling water (air cooler inlet)

temperature: 35 degC

3) Atmospheric pressure: 101.3 kPa (760 mm

Hg) |

|

|

|

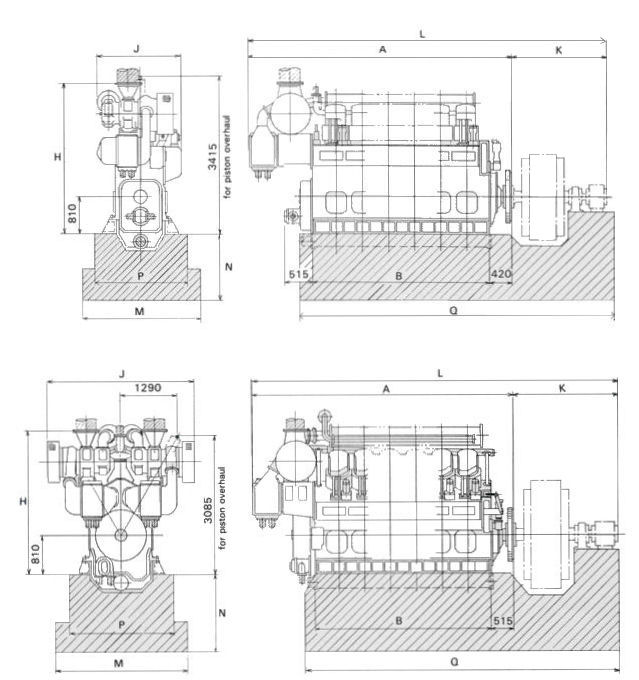

DIMENSIONS & MASS |

|

FOR GENERATION APPLICATION |

|

DIMENSIONS

MODEL |

A |

B |

H |

J |

K |

L |

M |

|

6L32CLX |

5 525 |

3 800 |

3 329 |

2 060 |

3 200 |

8 725 |

5 000 |

|

8L32CLX |

6 725 |

4 940 |

3 479 |

2 060 |

3 400 |

10 125 |

5 000 |

|

12V32CLX |

5 790 |

3 905 |

3 140 |

3 255 |

3 700 |

9 490 |

5 500 |

|

16V32CLX |

6 930 |

5 045 |

3 245 |

3 560 |

4 200 |

11 130 |

5 500 |

|

18V32CLX |

7 500 |

5 615 |

3 245 |

3 560 |

4 500 |

12 000 |

5 500 |

DIMENSIONS

MODEL |

N |

P |

Q |

Mass (t) |

|

Engine |

Generator |

|

6L32CLX |

3 000 |

3 500 |

8 400 |

30 |

12 |

|

8L32CLX |

3 000 |

3 500 |

9 700 |

40 |

16 |

|

12V32CLX |

3 500 |

4 000 |

8 700 |

48.5 |

19 |

|

16V32CLX |

3 500 |

4 000 |

10 500 |

58.5 |

22 |

|

18V32CLX |

3 500 |

4 000 |

11 700 |

63.5 |

25 |

Note:

1) The dimensions of foundation blocks shall be

subject to the geological conditions.

2) The mass and dimensions of generator shall be

subject to the electrical design.

| |

|

DESIGN & CONSTRUCTION FEATURES |

|

GENERAL |

The NIIGATA 32CLX diesel

engine is an ultra-modern, high power,

4-cycle, medium speed engine, designed to

provide reliable power for industrial or

marine service under long, arduous

conditions, anywhere throughout the world.

The design, based on many years of diesel

engine manufacture, incorporates maximum

reliability with minimum maintenance and

fuel consumption at low intial cost. |

| |

|

|

DESIGN AND CONSTRUCTION |

CYLINDER BLOCK (FRAME)

Rigid, box-girder section design with

mounting feet extended along the entire

length of the engine.

High grade cast iron, carrying the

crankshaft in main bearings, with

incorporated air intake trunk, lubricating

oil and coolant water channels.

All working parts inside the frame are

easily accessed through lightweight doors,

some incorporating explosion-proof valves,

provided at the front and rear of the frame.

|

|

CRANKSHAFT

One-piece, special forged steel,

manufactured by the 'R-R' process for

ensured strength.

Oil passages through the shaft provide

continuous oil feed to both connecting rod

bearings and pistons for optimum piston

crown cooling.

Balanced counterweights fitted on each web,

drastically reduces mechanical vibration.

A torsional vibration damper fitted to the

crankshaft's free end enhances crankshaft

and alternator shaft reliability.

|

MAIN BEARINGS

Shell type, steel-backed copper-lead alloy

with Pb-Snoverlay, housed in the frame and

caps.

This type of bearing provides ultra-strong

bearing force and long service life.

|

|

ANCHOR BEARING

A crankshaft anchor bearing, consisting of

the same shell type journal and thrust

bearings as the crankshaft, is supplied to

the coupling side of the frame for precise

crankshaft location and improved shaft

deflection.

|

CYLINDER HEADS AND VALVES

High grade cast iron cylinder heads provide

high thermal stress resistance.

Effective waterways are provided throughout

for totally adeguate coolant circulation.

The valve gear, with two intake and two

exhaust valves, is totally enclosed in a

cylinder head bonnet and lubricated by an

oil system independent from the engine oil

system.

The intake and exhaust manifolds are located

at the same side of the counter-camshaft and

arranged so that they may be left

undisturbed when one or more cylinder heads

are removed for partial disassembly.

A unique inlet and exhaust port arrangement

enables two types of valve to be used, one

being the inserted valve-seat type, of which

seat rings are inserted into the cylinder

head and directly cooled by the jacket

coolant.

The other available valve type is the

valve-cage type in which cages can be easily

withdrawn without necessitating removal of

the cylinder head, thereby providing easy

maintenance when using heavy fuel.

|

|

CONNECTING RODS

Made of special pressed steel, "I" section

connecting rod shank provide high regidity

and strength.

Large end bearing of a type similar to the

main bearing is secured by four high tensile

steel bolts.

Bush type small end bearing is

shrink-fitted.

The large-end 120-degree serrated matching

surfaces ensure high rigidity and serration

groove reliability.

|

CAMSHAFT(S)

Driven by a crankshaft gear through an idler

gear, individual case-hardened cams (intake,

exhaust, and fuel) are keyed onto the

camshaft.

The start-air distributor is located at the

shaft end.

The camshaft can be easily removed when

required. |

CYLINDER LINERS

Special cast iron, wet type liners are

precision-honed inside the bore.

Liners are secured to the top of the frame

by copper joints and are free to expand at

the lower end guide.

The upper section of the liners are provided

with a "Bore Cooling" system consisting of a

number of coolant passageways to ensure

moderate cooling.

|

|

FUEL INJECTION PUMPS

An individual Bosch type high pressure pump

is mounted at each cylinder, just above the

camshaft, and actuated by the camshaft's

fuel cam, enabling individual pump

adjustment for equal load distribution

across all cylinders.

|

FUEL INJECTORS

Fuel injectors consist of a nozzle and body.

When heavy fuel is used, nozzle temperature

is suitably controlled by the cylinder

coolant.

|

PISTONS

Two types of piston are avaliable, the

"composite type" with a heat-resistant steel

crown and ductile cast iron skirt, and the

ductile cast iron "mono-type" piston.

Both types are designed to reduce mechanical

and thermal stresses.

Cooling oil is induced into the cooling

chamber through the connecting rod for

optimum piston crown cooling.

Three compression and two oil scraper rings

are supplied.

Specially designed top rings minimize gas

blow-by through the ring gap.

Two coil expansion type oil scraper rings

ensure normal oil consumption. |

|

GOVERNOR

A camshaft-gear driven, Woodward-type

governor, controls the fuel pump's rackrod

through a interconnecting linkage.

Speed regulation is suitable for parallel

generator operation. Remote speed adjustment

is also provided for synchronization.

|

TURBOCHARGER(S)

Highly efficient, exhaust-gas driven, water

cooled, oil-bath lubricating type

turbocharger provided.

Either an air intake filter-silencer is

available, depending upon site conditions.

Either impulse or constant-pressure system

is provided, dependent upon engine

application.

|

|

|

|

|

|